IIS Manufactures & Supplies Compression Springs as per DIN 2095 & IS 7906

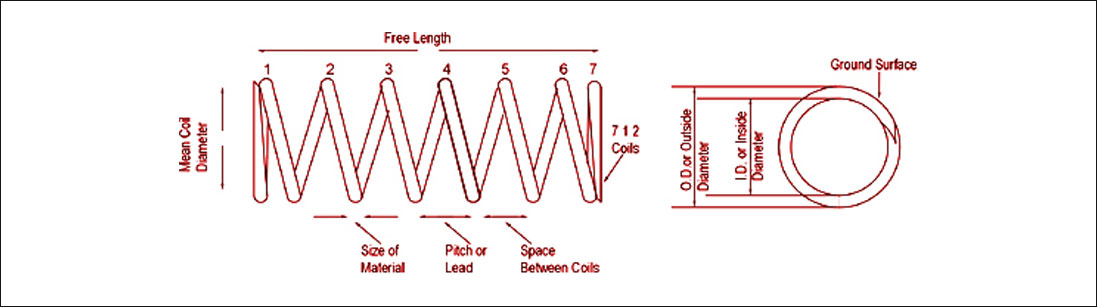

A compression spring offers resistance to the axial compressive force. It is an open-coil (pitch) helical spring. They are generally coiled as constant diameter cylinder.

Common forms

Conical, Concave (barrel), Convex (hourglass) and various combinations of above.

The space allotted will decide the allowable solid height, inner diameter and outer diameter of compression springs. Along with the load and deflection, the dimensional limits will decide the stress level. Therefore to avoid any design changes, sufficient care should be taken to decide allotted space.

Round wire is preferred over square, rectangular or some special section because of its easy availability.

Spring Materials

Common spring materials include stainless steel, alloy steels, carbon steels and some non-ferrous materials. IIS also produces spring from Exotic material like Inconel X-750, Inconel 718, Nimonic 90, Monel, Nimonic, Hastelloy, Beryllium copper etc.

Spring design

Selection of material is one of the important steps in spring Design. Types of material available, mechanical and electrical properties, operating conditions are few points of prime importance for material selection. In case of heavy stress cycles, a tight control is required in material quality. Scratches, seams and other such flaws affect fatigue life considerably. Carbon steel and alloy steel give optimum service and heavy stress cycles.

Stress Relieving

Coiling operation produces stress so springs must be stress relieved.�To relieve the harmful residual stresses, Stress Relieving of springs is done. Depending upon the type of spring material - furnace temperature & soaking time will vary accordingly. Stress relieving causes dimensional distortion so manufacturer should predict the change to achieve required dimensions. Forming should immediately follow stress relieving. We have in-house heat-treatment furnaces for large diameter springs. We also do shot penning on springs to introduce compressive stresses on the springs which help to increase the fatigue life of the springs.

IIS Capacity

We can manufacturing compression springs of any size, length and dimension you can think of. We have manufactured compression with OD of 500mm and length 1560mm.

IIS has automatic spring coilers upto 8.0mm wire diameter. From 8mm to 22mm we have semi-automatic cold coiling machines. From 22mm to 70mm we have hot coiling machines. IIS make coil springs from wire dia. 0.2mm upto 70mm

WE have load testing machines upto 100tons and we can test deflections upto 1200mm. Our automatic grinders can produce parallelism within 0.05mm and surface finish in microns.

WE have more than 47 years experience in the manufacturing of Compression springs.

Tolerances is are as per IS 7906 or DIN 2095

Surface coating

IIS offer a variety of coating on springs like Mechanical Zinc plating, Zinc Electro plating, Nickel Plating, Electrolesss Nickel plating, Geomet, Dacromet coating, Cadmium plating, Powder coating, Epoxy painting etc.