|

While designing

new machines and equipments, many designers don't provide

enough space for functioning of the springs, which results

into high cost, close tolerance springs and early failure.

In spite of having

different design techniques, materials and manufacturing

processes, all kinds of mechanical springs have some common

considerations.

A good spring

design should consider a lot of other things apart from

dimensional and load considerations.

Other areas of

considerations are

1. Operating environment in terms of temperature, corrosive

environment etc.

2. Frequency of Operations

3. Speed of load

4. Desired spring life.

An intelligent designer should consider all the above factors

and give better value for money to his customer. Here at

IIS we can help you design a variety of springs for almost

any type of application to suite you specific needs, Please

feel free to contact us.

Springs

selection, usage and life cycle

Generally, a product designer would like all the components

to last the life of the product. Thus it is expected that

the life of the spring must be equal or little less than

the life of the product for which it is used. Selection

of right manufacturer, who have an idea & experience

about the problems faced, is very important when a long

spring life is required. No spring manufacture can guarantee

zero failure in a batch of springs irrespective of time,

money and efforts taken to guarantee long life. Spring life

depends on many factors, which will eventually add to the

cost of springs. The detail test conditions, expected life

and failure rate must be clearly defined instead of vague

specifications. Intelligent design, right material and tight

quality control in material and production process can increase

the spring life. Predicting exact spring life has to be

done with careful consideration and with manufacturer's

consultation.

Material

:

Deciding the material is a crucial for a spring

designer. A List of material used by us to manufacturer

springs is available here

It is difficult to derive the amount of material required

to be used in a spring based on the load vs. deflection

requirement. Since Deflection is directly proportional to

load, the amount of material required to changes accordingly.

Different materials have different tensile strengths, which

are used in initial design calculations. The table below

shows the approximate tensile strengths.

Costs

Vs Tolerances

Springs must be produced in a cost effective way because

cost is a major factor in today's competitive environment.

Therefore generous tolerances must be given to allow manufacturer

springs by ordinary methods. It is always better to use

tolerances based on functional requirements. This will provide

an option to the manufacturer to make the necessary adjustments

in the variations in size and properties of material. Tight

tolerances reduce the production speed and rejection leading

to increased cost both to the manufacturer and the customer.

Burrs

:

While manufacturing springs,

several operations produce burrs. Since burrs are harmless

in nature, they are often neglected. Burrs formed after

spring end grinding or cutting can sometimes interfere with

the normal working of the springs by creating friction in

the guides or any parts holding the springs. It is necessary

for the manufacturer and the customer agree on the limits

of the burr based on the spring design and working.

Hydrogen

Embrittlement :

Hydrogen gets absorbed into material when carbon

steel is pickled for electroplating process preparation.

This leads to early failure of springs at lower tensile

stress even under short cycle tests. Many times the cracks

develop in pickling or plating bath but appear only after

plating or sometime when the plated springs are in use.

The risk of Hydrogen embrittlement is more when material

is subjected to high stress, is with high Rockwell Hardness

and has high carbon content. At equal hardness level, tempered

carbon steel has more chances of hydrogen embrittlement

than cold drawn carbon steel.

Hydrogen embrittlement cannot be checked quickly or detected

by a testing method. Scragging the springs up to the maximum

working load or up to the solid height for a long period

can surface any cracks cause due to hydrogen embrittlement.

To avoid failure due to hydrogen embrittlement it is important

to bake the spring immediately after plating to drive the

hydrogen out of the material.

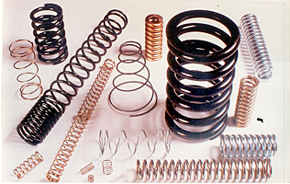

Different

Type of Springs for Different Applications :

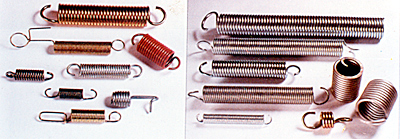

1. Compression & Extension Springs

(Round wire & Square or Rectangular Section)

2. Torsion Springs

3. Hot Coiled Springs

4. Spiral Springs

5. Power Springs

6. Constant Force Springs

7. Flat Springs

8. Disc Springs

9. Belleville Washer

10. Wave, Curved and Serrated Washers

11. Spring Dowel Pins

12. Wire forms

13. Strip Springs |

|

|